40 KG Flour Mixing Machine

Price 8000-125000 INR/ Piece

40 KG Flour Mixing Machine Specification

- Motor

- 2 HP Copper Winding

- Gross Weight

- 135 KG

- Product Type

- Flour Mixing Machine

- Material

- Stainless Steel

- Automatic Grade

- Semi-Automatic

- Power Source

- Electric

- Pressure

- Standard Atmospheric

- Voltage

- 220-240 V

- Capacity

- 40 KG per batch

- Rolling Range

- Can Mix 10-40 KG Flour

- Speed

- 1440 RPM

- Dimension (L*W*H)

- 40 x 24 x 34 inches

- Weight

- Approximately 120 KG

- Color

- Silver/Grey

- Bowl Material

- Food Grade Stainless Steel

- Control Panel

- Push Button Type

- Noise Level

- Low Noise Operation

- Maintenance

- Easy to Clean and Maintain

- Mixing Method

- Spiral Action

- Safety Features

- Overload Protection, Safety Cover

- Application

- Commercial Kitchen, Bakery, Restaurant Use

40 KG Flour Mixing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 8 Days

About 40 KG Flour Mixing Machine

Specification

Capacity | 40 Kg / 50 Kg |

Material | Body : M.S. Bowl : S.S. 202 |

Rotor, Gear Cover, Need Patti | S.S. 202 |

L x B x H | 50"x25"x38" / 50"x27"x39" |

Gear | Crown Premium |

Bowl Size | 27.5" x 18" / 28" x 19" |

Weight | 175 Kg. / 185 Kg. |

Motor | 3 HP |

Output RPM | 40 |

Atta Making Speed | 8 Minutes |

Powerful, Consistent Mixing for Professionals

This flour mixing machine utilizes spiral action to thoroughly knead dough, ensuring consistent texture and quality in every batch. Its durable 2 HP copper motor and automatic safety features make it ideal for commercial environments with heavy mixing demands. With a noise-minimizing design, it operates smoothly in busy kitchens without disturbance.

Hygienic and Robust Construction

Constructed entirely from food-grade stainless steel, including the mixing bowl, this mixer prevents rust and contamination. The premium build guarantees long-term durability and effortless cleaning, supporting rigorous hygiene standards essential in commercial kitchens and bakeries.

User-Friendly Operation and Maintenance

The semi-automatic, push button interface simplifies operation for staff, while features like overload protection and an easy-access safety cover promote safe use. Regular maintenance is streamlined by the accessible design, ensuring your mixer continues to perform well with minimal downtime.

FAQ's of 40 KG Flour Mixing Machine:

Q: How does the spiral mixing method benefit dough preparation?

A: The spiral action gently yet thoroughly mixes flour and water, developing gluten structure for uniform dough consistency. This technique is preferred in commercial bakeries for its efficiency, enabling quick processing of large batches without overworking the dough.Q: What types of establishments can use this 40 KG flour mixing machine?

A: This mixer is suitable for commercial kitchens, bakeries, and restaurants that require high-volume flour mixing. Its robust build and large capacity make it ideal for businesses producing breads, pastries, or other flour-based products daily.Q: What safety features are incorporated in this machine's design?

A: The machine includes multiple safety features: an overload protection system prevents motor damage from overuse, and a safety cover shields users from moving parts during operation, ensuring a secure environment for kitchen staff.Q: Where should the machine be installed for optimal performance?

A: Install the mixer on a flat, stable surface in a well-ventilated area, close to a 220-240 V electric outlet. Ensure there is space around the unit for easy cleaning and maintenance, and that staff can easily access the control panel and safety features.Q: What is the process for cleaning and maintaining the mixer?

A: To clean, disconnect the power supply and wipe down all stainless steel surfaces with a damp cloth and mild detergent. The bowl and exterior are designed for easy access, ensuring thorough sanitation. Routine maintenance involves inspecting moving parts and regularly checking the safety features.Q: When should the mixing machine be serviced?

A: It's recommended to inspect the mixer after every major use, and schedule full servicing (including motor and safety features) every six months to a year, depending on usage intensity, to maintain optimal operation and extend machine life.Q: What are the key benefits of using this flour mixing machine in a commercial setting?

A: This mixer offers efficient high-capacity mixing, consistent dough quality, improved operator safety, and reduced operational noise. Its robust stainless steel construction supports intensive use, while easy maintenance keeps downtime to a minimum, ultimately enhancing kitchen productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Flour Mixing Machine Category

2 KG Flour Mixing Machine

Price 8000-125000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 21 x 13 x 20 inch

Motor : 0.5 HP

Material : Stainless Steel

Weight : 35 kg

5 KG Flour Mixing Machine

Price 8000-125000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 24 x 15 x 19 inches

Motor : 0.5 HP Copper Motor

Material : Stainless Steel

Weight : Approx. 38 kg

10 KG Flour Mixing Machine

Price 8000-125000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 30 x 17 x 24 inch

Motor : 1 HP Single Phase

Material : Stainless Steel

Weight : Approx 85 Kg

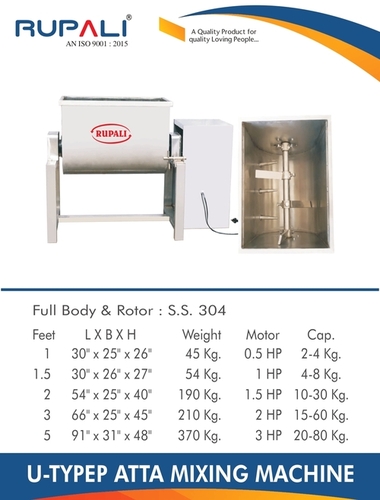

2-5 Feet U-Type Atta Mixing Machine

Price 8000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 54"x25"x40 Millimeter (mm)

Motor : 1.5 / 2 / 3 HP

Material : Stainless Steel

Weight : 190 / 210 / 370 Kilograms (kg)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS